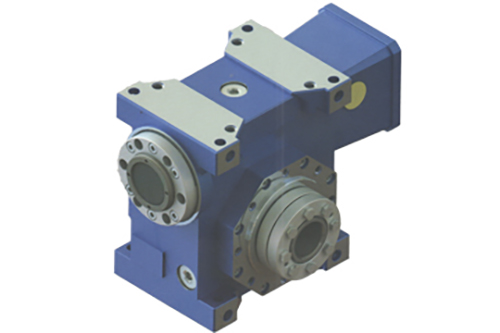

Low backlash right angle servo worm reducer

high precision worm equipment is an ideal replacement for precision planetary gearbox,the equipment manufacturer may substantially reduce the price tag on using precision planetary gearbox

The designer’s ideal solution is to rotate 90 degrees to set up the servo motor drive systems

Worm shaft in series could be driven by one motor to accomplish synchronous end result of multiple worm wheels. It’s been used in computerized polishing mobile phone shell and other equipments

Servo worm gear devices have three types : 45 – 50 – 55 – 63 – 75 – 90 ,with dual lead worm drive.Still left and right flank of worm shaft working with different lead angle,causing tooth thickness gradual modification,So that you can maneuver worm shaft and modify backlash.

Low backlash Features :

— Worm equipment gyration backlash could be adjusted to less than 1 arc.

— Reducer can be re-adjusted the gap after using .

— Input with coupling : reliable without backlash .

— Output using conical clamping ring couplings : reliable without backlash.

Applications :

Precision rotary motion

— Reducing the noise and vibration that’s caused by the strain change and the transformation of cutting force.

— reducing the sound and impact that is due to the corotation and reverse.

— By reducing worm abrasion.

— Increasing worm output response velocity .

Precision Indexing device

— CNC machine, assembly collection, cutting machine, transmission lines, etc.

— Indexing device,accurate studying mechanism require accurate movement occasions .

Speed changing situations

— Reducing the noises and the impact that is caused by speed change.

— Reducing the worm abrasion that is caused by speed changes.

Low rotation Make choice :

The following headings contain information on essential components for selection and correct utilization of gearbox.

For specific data on the gearbox range,start to see the relevant chapters.

OUTPUT TORQUE

1、Rated output torque

Mn2 [Nm]

The torque that can be transmitted continually through the output shaft, with the apparatus unit operated under a service factor fs = 1.

2、Required torque

Mr2 [Nm]

The torque demand predicated on application requirement. It is recommended to be add up to or significantly less than torque Mn2 the gearbox under research is rated for.

3、Calculated torque

Mc2 [Nm]

Computational torque value to be used when selecting the gearbox. It is calculated considering the needed torque Mr2 and service aspect fs, as per the partnership here after:

POWER

1、Rated input power

Pn1 [kW]

The parameter can be found in the gearbox rating charts and represents the KW which can be safely transmitted to the gearbox, predicated on input speed n1 and service factor fs= 1.

2、Rated output power

Pn2 [kW]

This value may be the power transmitted at gearbox output. it really is calculated with the following formulas:

EFFICIENCY

Efficiency is a parameter that includes a major affect on the sizing of certain applications, and basically is determined by gear pair designelements.

The mesh data table on page 9 shows dynamic efficiency (n1=1400)and static efficiency values.

Remember that these values are just achieved following the unit has been run found in and is at the working temperature.

1、Dynamic efficiency

[ηd]

The dynamic efficiency may be the relationship of power delivered at output shaft P2 to power applied at input shaft P1:

2、Static efficiency

[ηs]

Efficiency obtained in start-up of the gearbox. Although this is generally not really significant component for helical gears, it might be instead critical when choosing worm gearmotors operating under intermittent duty.

SERVICE FACTOR [ fs ]

The service factor (fs ) depends on the operating conditions the gearbox is subjected to the parameters that require to be taken into consideration to select the most sufficient servies factor properly comprise:

1. kind of load of the operated equipment : A – B – C

2. length of daily operating time: hours/day(△)

3. start-up frequency: starts/hour (*)

TYPE OF LOAD: A good – uniform, fa≤0.3

B – moderate shocks, fa≤3

C – large shocks, fa≤10

fa=Je/Jm

–Je(kgm2) point in time of the external inertia reduced at the travel shaft

–Jm(kgm2) minute of inertia of motor

–If fa>10 please contact our Technical Service

A good -Screw feeders for light components, supporters, assembly lines, conveyor belts for light materials, small mixers, lifts, cleaning machines, fillers, control machines.

B -Winding gadgets, woodworking machine feeders, goods lifts, balancers,threading equipment, method mixers, conveyor belts for heavy materials,winches, sliding doorways, fertilizer scrapers, packing machines, concrete mixers, crane mechanisms, milling cutters, folding machines, equipment pumps.

C -Mixers for heavy components, shears, presses,  centrifuges, rotating helps, winches and lifts for large materials, grinding lathes, natural stone mills, bucket elevators, drilling equipment, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

centrifuges, rotating helps, winches and lifts for large materials, grinding lathes, natural stone mills, bucket elevators, drilling equipment, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

series includes a 90 degree input via helical bevel equipment,and its giant tapered roller bearings also make it ideal for large radial and axial forces. PAR right position reducer features an extremely short, light but rigid housing and full compatibility with standard engine adapters.PAR right angle planetary gearbox combines the features of a compact right position gearbox and the ones of a typical planetary gearbox.Highest Precision, Highest Torque and Quiet Operation are provided by 100% optimized Helical Gearing.

With the compact structure but powerful design, PAR right angle planetary gearbox is ideal option for movement control applications wherein the energy flow should be redirected. So that it can support users to save the running price and enhance the transmission efficiency. The input flange sizes of PAR correct angle gearbox is open to be customized, subsequently, it is appropriate for any makes of the servo motors, brushless DC motors and stepper motors.

1) High quality light weight aluminum alloy die cast gearbox

2) High accuracy worm gear and worm shaft

3) Less noises and lower temperature increase

4) Easy installation and linking, high efficiency

5) Power: 0.06-16 kW

6) Output torque: 1.8-1, 596 N. M

Output speed: 14-280rpm

If Double Gearbox, output speed: 0.3-14rpm.

7) Ratio: 5-100

8) Inner packing: Carton; Outer packing: Plywood circumstance.

9) Model amount: RV 030, 040, 050, 063, 075, 090, 110, 130, 150

1,Worm gear gyration backlash could be adjusted to significantly less than 1 arc.

2,Reducer could be re-adjusted the gap after using.

3,Insight with coupling : reliable without backlash.

4,Output working with conical clamping ring couplings : reliable without backlash.

5,Torque up to 7300Nm.

6,With servo coupling input.

7,Shrink disc(optional) for easy intergration.

8,Dual lead worm drive.

9,The ideal solution to lessen costs in servomotor application instead of bevel planetary gearheads.